Spray Paint Booths

Prefabricated + Custom Engineered + Modernization

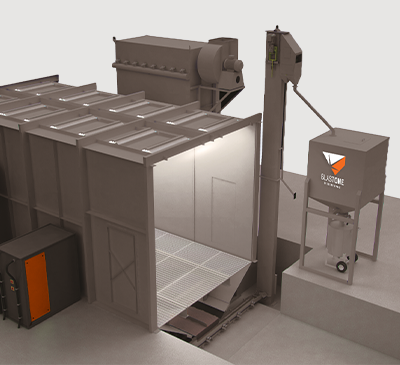

BlastOne has nearly 50 years of experience in design, engineering, and servicing paint rooms and booths in America, Australia, and globally. BlastOne is the undistributed industry expert. BlastOne has a unique process to conceptualize design and build high-performance spray paint rooms and booths for many industrial applications – from small, containerized rooms to multi-million-dollar paint facilities.

My Account

My Account